Unmanned smart dock. Provided by the interviewed unit

The world's largest liquefied natural gas project - the Yamal project in Russia, the largest deepwater oil and gas platform in Asia - the Liwan 3-1 platform project in the South China Sea, China's first self-designed and constructed deepwater semi submersible drilling platform - Offshore Oil 981. The offshore steel provided by Xiangtan Iron and Steel Group Co., Ltd. (hereinafter referred to as "Xiangtan Iron and Steel") has been successfully applied to these projects.

The world's longest cross sea bridge - the Hong Kong Zhuhai Macao Bridge, the world's first six line railway bridge - the Nanjing Dashengguan Bridge, the world's largest single span railway bridge - the Hongqili Bridge, and the bridge steel used on the Beijing Shanghai high-speed railway all have the presence of the Xianggang series products.

The Qatar Shopping Center, the world's largest shopping center, the Shanghai center Tower, the second tallest building in the world and the highest building in China, and Beijing Daxing International Airport, the world's largest aviation hub, also use structural steel produced by Xianggang in a large number of well-known buildings.

Xianggang's products have become a major steel supplier in a series of fields, including the world's shipbuilding industry's "crown jewel" - super LNG ships, the largest spherical tank group project in Asia - Ningbo Haiyue Spherical Tank Group, and the highest grade pipeline steel X80 used in the China Russia East Gas Pipeline Project.

……

How did Xianggang escape the "acceleration" in the overall downturn of the steel industry? It is precisely with the goal of promoting the "Four Modernizations and Two Priorities" (high-end quality and brand, intelligent equipment processes, green production and manufacturing, and service-oriented operation management, leading state-owned enterprises in party committee work, and industry-leading comprehensive strength) that the goal of leading the steel industry is achieved. The party committee work of "Party and government work together, striving for excellence and performance" is planned, deployed, and implemented together with production and operation, forming a strong synergy for innovative development, thereby greatly enhancing the core competitiveness and profitability of the enterprise.

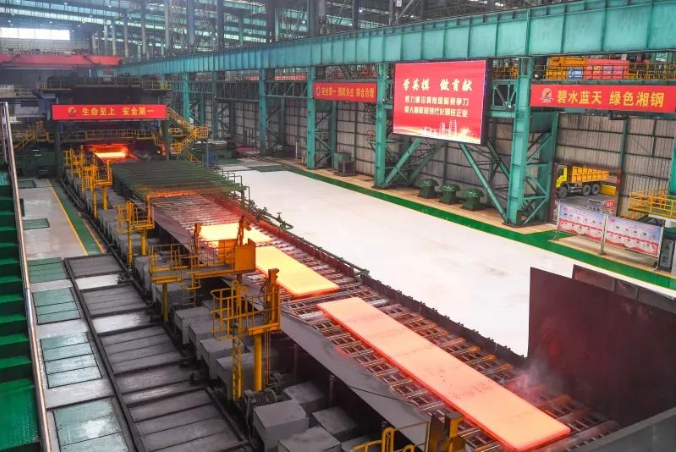

The steel rolling production line of Wumi Plate Factory. Provided by the interviewed unit

Integrating Party and Government into One Field, Striving for Excellence and Creating Performance

"We conduct daily handover of production line teams in the party building room, which not only enhances the sense of mission and responsibility of party members and all employees, but also enhances the level of independent management of employees, achieving a dual improvement of party building and production and operation." Fang Hua, the secretary of the party branch of the steel rolling workshop of Xianggang's 5-meter wide and thick plate plant, pointed to the room next to the large steel rolling equipment and said.

Entering the party building room located next to the production line, the party affairs public column on the wall contains tables such as the party branch's work plan, party member commitments, monthly lessons and practice, and party member point management, which record in detail the party affairs of the branch every month; In addition, the introduction of the party branch in the steel rolling workshop, the party member responsibility area, and the joint project of the branch secretary are all detailed on the wall.

The most eye-catching achievement is the commitment indicators of the 28 party members of the branch in 2023. The table provides a detailed list of the indicator names, planned values, target values, and world industry advanced levels for each link in the steel rolling production process, corresponding to the personal commitments of workshop secretaries, directors, technicians, engineers, safety officers, and other positions. Each person has their own target values for their efforts.

"This allows party members to play a pioneering and exemplary role in different positions in the workshop, effectively driving the work enthusiasm of other employees, and forming an organic combination of party building and production and operation." Zeng Wenping, the head of the Party and Youth League Work Department of Xianggang Comprehensive Management Department, said that all party branches of Xianggang have formed a fusion of party building work and production and operation work, and party building studios like this can be seen everywhere in Xianggang.

The formation of the party building characteristics of this branch stems from Xianggang's adherence to the party committee work philosophy of "integrating party and government, striving for excellence, and creating performance". This philosophy is derived from Xianggang's continuous innovation and development in inheritance, and is an important guide and fundamental principle for promoting party and government integration and promoting Xianggang's reform and development.

Workshop Party Building Office. Provided by the interviewed unit

The integration of party and government into one piece of land is to guide the party and government to achieve the same goals, share the same responsibilities, and cooperate with the same frequency. It focuses on the comprehensive and strict governance of the party and the reform and development of enterprises, and combines party building and ideological and political work with the production, operation, and reform management of Xianggang, making scientific decisions and promoting together.

Nowadays, at the beginning of each year, Xianggang conducts research and decomposition on party building work and key production and operation work, closely integrating the requirements of party organizations with the actual situation of the enterprise, leading party organizations at all levels to carry out various distinctive party building activities such as "Party Member Pioneer Tour" and "Party Member Points Management" around the characteristics of the unit, and exploring the establishment of a group of more distinctive and effective typical practices.

"Striving for excellence and creating performance" is to integrate the core values of "striving for excellence" into the work philosophy of the Xianggang Party Committee, inspire party organizations at all levels and all party members to strive for "striving" party organizations and become "striving" party members, unite and lead the majority of employees to work together, and promote the continuous development of the enterprise.

"The Party Committee of Xianggang has 31 second level Party committees and 4 Party branches, 255 Party branches, and more than 7000 Party members. Through this Party Committee work philosophy, it has effectively solved the problem of" two skins "in Party building and production, played the role of a fighting fortress for enterprise Party organizations, effectively promoted enterprises to fight various tough battles, and ensured enterprise reform, development, and stability." Zhang Zhigang, Deputy Secretary of the Party Committee of Xianggang (the company's main position), said.

The steel rolling production line of Wumi Plate Factory. Provided by the interviewed unit

Smart upgrading improves efficiency, technological innovation seeks market share

Looking down at the production line of the steel rolling workshop of Xianggang's 5-meter wide and thick plate factory, the red steel plate can be turned into several millimeters of "thin sheets" after multiple rolling processes. The excess steel plate tailings that are cut off during the rolling process are stored in a centralized manner and transported to the designated area by the overhead crane in the workshop for further "reheating" to become new steel plates.

Surprisingly, there was no driver seen on the moving overhead crane in the high-temperature workshop of the steel rolling production line, only the crane and grabbing equipment that were working on the move; In the intelligent control center of a five meter wide and thick plate factory located 1 kilometer away, the crane operator sits in front of the control panel and remotely controls the crane disk, with videos from multiple angles assisting him in his operations.

As the "nerve center" of the five meter wide and thick plate factory, monitoring and operators here can remotely command multiple processes such as steelmaking, rolling, finished product transportation, and warehousing through the monitoring screen. Peng Dun, the technical director of the intelligent control center, said, "With the construction and use of digital visualization production lines, the production efficiency of the workshop has improved by 20% compared to before, and workers have also moved away from noisy and high-temperature working environments, greatly improving work comfort."

It is understood that in 2016, Xianggang began to vigorously promote the construction of smart factories, with a total of 363 projects approved and a total investment of 760 million yuan. With the idea of "building a digital cloud platform, connecting an industrial Internet private network, improving three data centers, upgrading five management systems, constructing multiple smart production lines, and promoting the implementation of a large number of digital applications", Xianggang aims to improve the level of on-site automation, management digitization, and system intelligence.

Nowadays, a series of innovative application scenarios, such as unmanned overhead cranes, intelligent grading of scrap steel, unmanned slab warehouses, online monitoring of equipment status, and automatic drone inspections, have been successfully used in Xianggang. The labor production efficiency has increased from 838 tons of steel per person per year in 2016 to 1658 tons of steel per person per year by the end of 2022, with economic benefits of over 1 billion yuan and optimized job positions of about 1000 people.

The operator of the Wumi board factory performs unmanned intelligent overhead crane operation. Provided by the interviewed unit

At the same time as the intelligent upgrade of the workshop, Xianggang is also adhering to customer demand orientation, increasing technological innovation efforts, and achieving breakthroughs in a large number of key technologies, with major research and development achievements constantly emerging; With the continuous investment of resources by enterprises, accelerating the construction of high-level R&D platforms and the introduction of high-end talents, a continuous stream of technical support has been provided for product research and development.

Liuhua Oilfield, located in the the Pearl River Mouth Basin in the South China Sea, is the first project in China to use 420MPa high strength marine steel as the main steel. After receiving the research and development task for steel for deep-water jackets from the project department, Xianggang actively developed a research and development plan and schedule. In less than three months, they successfully developed API 2Y-60 high-strength marine steel for 100mm thick deep-water jackets and passed CCS third-party certification.

Wang Zhen, the director of the Plate Research and Development Office at Xianggang Technology Center, said, "Xianggang API 2Y-60 high-strength marine engineering steel has successfully passed the welding test at the marine engineering site in one go, and has become the only steel enterprise invited to participate in the S420 localization feasibility technical exchange meeting due to outstanding performance in research and development efficiency, quality performance, and other aspects. It has received unanimous praise from attending marine engineering experts and scholars."

In the past three years, Xianggang has developed more than 90 new products, achieved import substitution for multiple varieties, and successfully solved multiple "bottleneck" core technical problems. By focusing on the strategy of building a strong manufacturing country, closely monitoring the current trend of steel development in the steel industry, focusing on the research and development of key technologies and cutting-edge products for large-scale equipment, extreme service environments, and lightweight equipment, Xianggang has promoted the development of plate products towards "specialization, precision, and strength", and achieved further breakthroughs in product research and development.

The Yamal project in Russia. Provided by the interviewed unit

Actively expand the international market, and accelerate the "the Belt and Road" to go global

"The 100mm thick anti cracking steel of Xianggang has been certified by classification societies in multiple countries such as the United States, France, and Norway, and its technology has reached the world's top level." The news came as the members of Xianggang's anti cracking steel research and development team were excited. It is understood that since 2023, the new orders and supply of Xianggang's crack prevention steel have been increasing, marking the stability of Xianggang's ability to accept orders and deliver thick crack prevention steel in the domestic first tier.

It is understood that maritime transportation, relying on its advantages of high efficiency and minimal cargo damage, has always been the most widely used method in the international freight industry. With the advancement of globalization, the trend of large-scale ships has already become. According to the requirements of the International Association of Classification Societies, the upper deck structure of ultra large container ships with a carrying capacity of over 10000 TEUs must be made of thick and high-strength steel plates with high crack resistance toughness. Due to the great difficulty in research and development and production of this product, it poses a challenge to the capabilities of global steel enterprises.

In order to overcome the technical difficulties in this field, Xianggang has continuously invested research and development efforts, relying on a series of advanced new technologies and production processes to gradually overcome a series of technical difficulties, achieve new breakthroughs in core indicators, and take the lead in developing 80mm thick EH47BCA1 high crack resistance toughness steel plate in China.

"The high anti cracking toughness and thick steel plates we produce not only provide assurance for the core key materials urgently needed by downstream industries to build high-tech ships, but also provide strong support for the 100% localization of anti cracking steel plates for domestic ultra large container ships. In the future, this product has great potential in overseas markets." said Luo Deng, Secretary of the Party Committee of Xianggang Technology Center. Currently, only a single digit of enterprises worldwide have stable production capacity for 100mm thick high anti cracking toughness steel plates, and Xianggang has become one of them.

With the continuous enrichment of high-end steel products at Xianggang, many products have gradually become "little giants" in the steel subdivision field, providing strong support for enterprises to go out and participate in international competition. Today, the international market share of Xianggang's products is growing gradually, especially the construction of the "the Belt and Road" has brought huge opportunities for Xianggang to go global at a higher level.

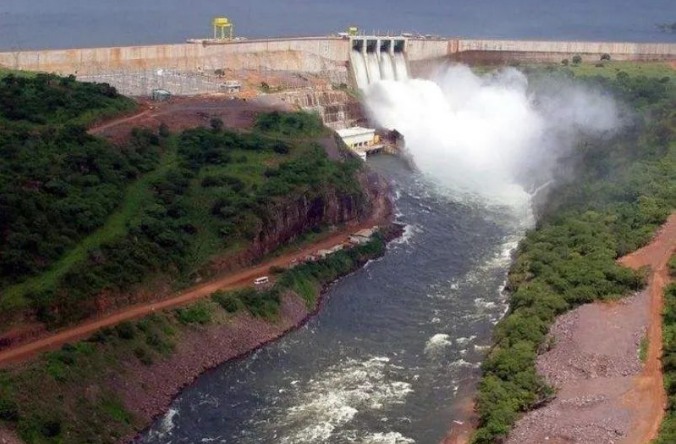

The Nirum Jelem Hydroelectric Power Station Project in Pakistan. Provided by the interviewed unit

In October 2022, a special export container train loaded with Xianggang steel wire rods and plates slowly departed from Zhuzhou North Station, passed through the Hunan Guangdong non rail sea intermodal transportation channel, boarded a ship from Nansha Port in Guangzhou, and set sail. It will then arrive at Linchaban in Thailand and Gudan Port in Brazil, Malaysia. This is the first time that Hunan Steel has been transported to Southeast Asia through railway containers.

At the same time, at the Shunxiang Port in Xiangjiang, Hunan, thousands of ton ships shuttle back and forth, transporting Xianggang's wire, bar, plate and other products to Shanghai, and then shipping them by sea to Japan, South Korea, Southeast Asia, and other countries; Another route is to export steel products from Shanghai, through the Strait of Malacca and the Indian Ocean, to countries such as the United Arab Emirates, Saudi Arabia, and Qatar.

With the release of the demand for infrastructure construction in Central Asia, South Asia, Southeast Asia and other regions, and the gradient transfer of the global wild goose array industry, the countries along the "the Belt and Road" have become a new growth point of global steel consumption. Xianggang is seizing this opportunity to vigorously expand its international export business.

"Today, Xianggang products are available in key projects of countries along the" the Belt and Road ", such as the headquarters building of the Asian Investment Bank, the Huangjing Port of Malaysia, and the Thai Petroleum Platform. We have been extensively involved in major projects in Thailand, Bangladesh, Central Asian countries, and Western Asia." Zhao Liang, head of overseas sales of Xianggang International Trade Corporation, said: "At present, Xianggang is expected to achieve a profit of 3.2 billion yuan and export 750000 tons from January to November 2023 by virtue of the east wind of the" the Belt and Road "."